No products

Product successfully added to your shopping cart

View larger

View larger

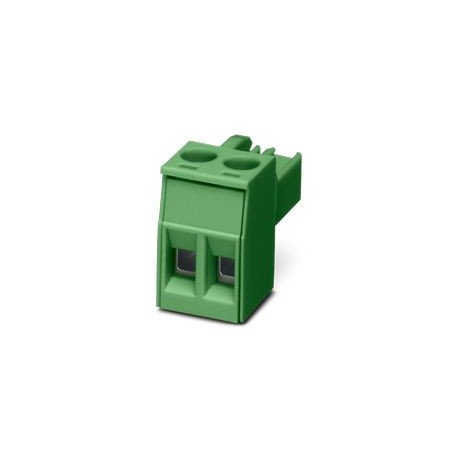

MSTBT 2,5 HC/ 2-STP GN 1499476 PHOENIX CONTACT PCB connector, nominal cross-section: 2.5 mm², colour: green,..

MSTBT 2,5 HC/ 2-STP GN

1499476

PHOENIX_CONTACT

50

PCB connector, nominal cross-section: 2.5 mm², colour: green, nominal current: 16 A, nominal voltage (III/2): 320 V, surface contacts: Tin, contact type: Female, number of rows: 1, number of poles: 2, article family: MSTBT 2.5 HC/.. -STP, pitch: 5mm, connection type: Screw connection with pull capsule, driver/PCB connection direction: 0°, clamping hook: - Clamping hook, plug-in system: COMBICON MSTB 2.5 HC, locking: without, fastening type: without, packing type: boxed

Housing (HS)

* Brand new product in its original packaging covered by the warranties and certifications provided by PHOENIX_CONTACT

Related products

▲More info

▲| Construction | Standard |

| Product Line | COMBICON Connectors M |

| Product Type | Printed Circuit Board Connector |

| Product Family | MSTBT 2.5 HC/.. -STP |

| Number of poles | 2 |

| Step | 5 mm |

| Number of rows | 1 |

| Clamping flange | without |

| Nominal Current IN | 16 A |

| Nominal voltage UN | 250 V |

| Degree of pollution | 3 |

| Contact resistance | 1.2 mΩ |

| Sizing voltage (III/3) | 250 V |

| Dimensioning transient voltage (III/3) | 4 kV |

| Dimensioning voltage (III/2) | 320 V |

| Dimensioning Transient Voltage (III/2) | 4 kV |

| Nominal voltage (II/2) | 630 V |

| Dimensioning transient voltage (II/2) | 4 kV |

| Connection technology | |

| Construction | Standard |

| Connector System | COMBICON MSTB 2,5 HC |

| Nominal Section | 2.5 mm² |

| Contact Connection Type | Female |

| Blockade | |

| Locking system | without |

| Clamping flange | without |

| Connecting Conductors | |

| Connection type | Screw connection with traction capsule |

| Connection Direction Driver/PCB | 0 ° |

| Rigid conductor section | 0.2 mm² ... 2.5 mm² |

| Flexible conductor section | 0.2 mm² ... 2.5 mm² |

| AWG Conductor Section | 24 ... 12 |

| Flexible conductor section with toe cap, without plastic sleeve | 0.25 mm² ... 2.5 mm² |

| Flexible conductor section with toe cap, with plastic sleeve | 0.25 mm² ... 2.5 mm² |

| 2 conductors with the same cross-section, rigid | 0.2 mm² ... 1 mm² |

| 2 conductors with the same cross-section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors of equal cross-section, flexible with toe cap, without plastic sleeve | 0.25 mm² ... 1 mm² |

| 2 conductors with the same cross-section, flexible with TWIN toe cap with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Male gauge a x b / Diameter | 2.8 mm x 2.0 mm / 2.4 mm |

| Peel Length | 7 mm |

| Tightening torque | 0.5 Nm ... 0.6 Nm |

| Material data - contact | |

| Observation | WEEE/RoHS compliant, filament-free according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu Alloy |

| Surface Characteristics | Malleable cast iron tinning |

| Metal surface of the terminal point (top layer) | Tin (4 - 8 μm Sn) |

| Metal surface contact area (top layer) | Tin (4 - 8 μm Sn) |

| Material data - housing | |

| Color (Housing) | Light Grey (7035) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability class according to UL 94 | V0 |

| Flammability number of GWFI incandescent filaments according to EN 60695-2-12 | 850 |

| Ignition temperature of incandescent filaments GWIT according to EN 60695-2-13 | 775 |

| Ball hardness test temperature according to EN 60695-10-2 | 125 °C |

| Dimension Scheme |  |

| Step | 5 mm |

| Width [w] | 10 mm |

| Height [h] | 15 mm |

| Length [l] | 18.1 mm |

| Connection type | Screw connection with traction capsule |

| Observation regarding the operation | According to DIN EN 61984, COMBICON connectors are connectors without switching power (COC). In the event of use as prescribed, they must not be plugged in or unplugged under voltage or load. |

| Safety Indication | |

| Safety Notes | WARNING: Connectors should not be plugged in or unplugged under load. Failure to comply and improper use can result in property damage and personal injury. |

| • WARNING: Serve only products in perfect condition. Products should be checked regularly for damage. Remove defective products immediately. Replace damaged products. It is not possible to repair them. | |

| • WARNING: only qualified personnel specialized in electrical engineering can install and use the product, always taking into account the following safety indications. Specialized personnel must be familiar with the fundamentals of electrical engineering. You must be able to identify and avoid hazards. The corresponding symbol on the packaging indicates that personnel specialized in electrical engineering are required for installation and operation. | |

| • The item is intended as an unencapsulated plug for mounting in a housing. | |

| • Use connectors only fully plugged in. | |

| Checking for damage to conductors and loosening | |

| Test Specification | DIN EN 60999-1 (VDE 0609-1):2000-12 |

| Result | Approved Test |

| Tensile Test | |

| Test Specification | DIN EN 60999-1 (VDE 0609-1):2000-12 |

| Conductor Section/Conductor Type/Tensile Force Nominal Value/Actual Value | 0.2 mm² / rigid / > 10 N |

| 0.2 mm² / flexible / > 10 N | |

| 2.5 mm² / rigid / > 50 N | |

| 2.5 mm² / flexible / > 50 N | |

| Forces when plugging in and unplugging | |

| Result | Approved Test |

| Number of cycles | 25 |

| Plug-in force approx. | 11 N |

| Power when unplugging by pole approx. | 7 N |

| Torque check | |

| Test Specification | DIN EN 60999-1 (VDE 0609-1):2000-12 |

| Resistance of the signs | |

| Test Specification | DIN EN 60068-2-70:1996-07 |

| Result | Approved Test |

| Polarization & Coding | |

| Test Specification | DIN EN 60512-13-5:2006-11 |

| Result | Approved Test |

| Eye Exam | |

| Test Specification | DIN EN 60512-1-1:2003-01 |

| Result | Approved Test |

| Dimensional Examination | |

| Test Specification | DIN EN 60512-1-2:2003-01 |

| Result | Approved Test |

| Vibration test | |

| Test Specification | DIN EN 60068-2-6 (VDE 0468-2-6):2008-10 |

| frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Sweep speed | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Durability Test | |

| Test Specification | DIN EN 60512-9-1 (VDE 0687-512-9-1):2010-12 |

| Bearable shock voltage at sea level | 4.8 kV |

| Contact Resistance R1 | 1.2 mΩ |

| Contact Resistance R2 | 1.23 mΩ |

| Plug Cycles | 25 |

| Insulation Resistance Adjacent Poles | > 21 TΩ |

| Climate Essay | |

| Test Specification | DIN EN ISO 6988:1997-03 |

| Corrosion fatigue | 1.0 dm3UNDER2in 300 dm3/40 °C/3 cycles |

| Thermal stress | 100 °C/168 h |

| Bearable AC voltage | 3.1 kV |

| Environmental conditions | |

| Ambient Temperature (Service) | -40 °C ... 105 °C (depending on the rating curve) |

| Ambient Temperature (Storage/Transport) | -40 °C ... 55 °C |

| Relative humidity of the air (storage/transport) | 30 % ... 70 % |

| Ambient Temperature (Mounting) | -5 °C ... 100 °C |

| Thermal Test | Test Group C | |

| Test Specification | DIN EN 60512-5-1:2003-01 |

| Number of poles tested | 4 |

| Insulation resistance | |

| Test Specification | DIN EN 60512-3-1:2003-01 |

| Insulation Resistance Adjacent Poles | > 21 TΩ |

| Creepage Lines & Air Isolation Distances | | |

| Test Specification | DIN EN 60664-1 (VDE 0110-1):2008-01 |

| Insulating material group | I |

| Resistance to leakage currents (DIN EN 60112 (VDE 0303-11)) | CTI 600 |

| Sizing Insulation Voltage (III/3) | 250 V |

| Nominal transient voltage (III/3) | 4 kV |

| minimum value of air insulation distance - non-homogeneous field (III/3) | 3 mm |

| Minimum creepage line value (III/3) | 3.2 mm |

| Sizing Insulation Voltage (III/2) | 320 V |

| Nominal transient voltage (III/2) | 4 kV |

| Minimum Value of Air Insulation Distance - Non-Homogeneous Field (III/2) | 3 mm |

| Minimum creepage line value (III/2) | 1.6 mm |

| Sizing Insulation Voltage (II/2) | 630 V |

| Nominal transient voltage (II/2) | 4 kV |

| Minimum Value of Air Insulation Distance - Non-Homogeneous Field (II/2) | 3 mm |

| Minimum creepage line value (II/2) | 3.2 mm |

| Type of packaging | Boxed Packaging |

Datasheet - PDF

▲| Title: | Size: | Type: |

|---|---|---|

| PDF CATALOG PHOENIX INTERFACE TECHNOLOGY AND SWITCHING DEVICES EN.pdf | 27 Mbytes |

|

Reviews (0) ▲

No customer reviews for the moment.

| Rating: |

|

| Name: | |

| Email: | |

| Subject: | |

| Text: | |

| Do you recommend this product to buy? | |

|

|

|

| Add review | |

All ratings we receive from the items we offer are real and verified. A small gesture, but a lot of value. That's why we thank you for that minute you invest in leaving us your opinion and qualification about the products, because it helps us to continue improving and to offer you a service of even higher quality.