No products

Product successfully added to your shopping cart

View larger

View larger

A4EG-BE2R041 247805 OMRON Security Product, Command validation E-stop

A4EG-BE2R041

247805

OMRON

Security Product, Command validation E-stop

Safety > Others Safety

* Brand new product in its original packaging covered by the warranties and certifications provided by OMRON

Best sellers

▲More info

▲Safety guard switching unit

The safety controller to support maintenance mode and normal operation mode in a safe way.

- Two operation modes to support auto switching for applications where machine an worker co-operate and manual switching for applications with limitaions in operation like maintenance

- Clear LED diagnosis of all in- and outputs

- Applicable up to Category 4 acc. EN 954-1

Enabling grip switches

Safety guard switching units

Safety outputs1 | Auxiliary outputs2 | Max. OFF | ||||||

|---|---|---|---|---|---|---|---|---|

OFF-delayed4 | ||||||||

Specifications

Ratings of guard switching unit

Power input

Inputs

Operating voltage: 20.4 VDC to 26.4 VDC, internal impedance: approx. 2.8 kΩ | |

Outputs

Application example

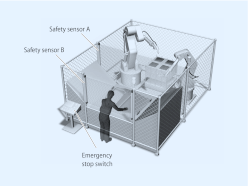

Automatic switching mode

Worker is loading and unloading the machine manually. When loading is finished, robot cycle is started manually by the worker. When robots return to their home position, loading cycle is selected automatically.

Loading condition: Safety sensor B is not active, safety sensor A is active because the robots are not allowed to move to the loading area while the worker loads the machine. So the worker is safe because safety sensor A is active.

Robot work condition: Safety sensor B is active, safety sensor A is not active because the worker is not allowed to move to the loading area when the robots work. So the worker is safe because safety sensor B stops the machine if he moves to the loading area.

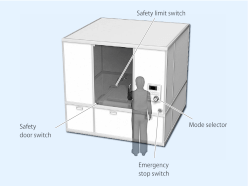

Manual switching mode

Worker has to do maintenance in this machine. While maintenance, it is necessary to move the machine in a limited way. The worker has to select automatic mode or manual mode manually by using the mode selector switch.

Operation steps:

1)Select maintenance mode by using the mode selector

2)Open the door to do the maintenance while the machine still is able to operate in a limited way (monitoring of limited movement by using the safety limit switch).

3)Close the cover after finishing maintenance

4)Select automatic mode by using the mode selector

E-Stop conditions:

a)open the door while not in maintenance mode

b)the machine actuates the limit switch (breaks the limit).

c)the Enabling grip switch A4EG is actuated to stop the machine in emergency condition.

Datasheet - PDF

▲| Title: | Size: | Type: |

|---|---|---|

| PDF CATALOGO OMRON AUTOMATION EN.pdf | 28 Mbytes |

|

| PDF CATALOG OMRON EN.pdf | 24 Mbytes |

|

| A4EG-BE2R041 247805 | 240 Kbytes |

|

| A4EG-BE2R041 247805 a4eg_datasheet_en.pdf | 3 Mbytes |

|

Reviews (0) ▲

No customer reviews for the moment.

| Rating: |

|

| Name: | |

| Email: | |

| Subject: | |

| Text: | |

| Do you recommend this product to buy? | |

|

|

|

| Add review | |

All ratings we receive from the items we offer are real and verified. A small gesture, but a lot of value. That's why we thank you for that minute you invest in leaving us your opinion and qualification about the products, because it helps us to continue improving and to offer you a service of even higher quality.