Technical data for design verification

Rated operational current for specified heat dissipation [In]

6 A

Heat dissipation per pole, current-dependent [Pvid]

0.13 W

Equipment heat dissipation, current-dependent [Pvid]

0 W

Static heat dissipation, non-current-dependent [Pvs]

0 W

Heat dissipation capacity [Pdiss]

0 W

Operating ambient temperature min.

-25 °C

Operating ambient temperature max.

+70 °C

IEC/EN 61439 design verification

10.2 Strength of materials and parts10.2.2 Corrosion resistance

Meets the product standard's requirements.

10.2 Strength of materials and parts10.2.3.1 Verification of thermal stability of enclosures

Meets the product standard's requirements.

10.2 Strength of materials and parts10.2.3.2 Verification of resistance of insulating materials to normal heat

Meets the product standard's requirements.

10.2 Strength of materials and parts10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects

Meets the product standard's requirements.

10.2 Strength of materials and parts10.2.4 Resistance to ultra-violet (UV) radiation

Meets the product standard's requirements.

10.2 Strength of materials and parts10.2.5 Lifting

Does not apply, since the entire switchgear needs to be evaluated.

10.2 Strength of materials and parts10.2.6 Mechanical impact

Does not apply, since the entire switchgear needs to be evaluated.

10.2 Strength of materials and parts10.2.7 Inscriptions

Meets the product standard's requirements.

10.3 Degree of protection of ASSEMBLIES

Does not apply, since the entire switchgear needs to be evaluated.

10.4 Clearances and creepage distances

Meets the product standard's requirements.

10.5 Protection against electric shock

Does not apply, since the entire switchgear needs to be evaluated.

10.6 Incorporation of switching devices and components

Does not apply, since the entire switchgear needs to be evaluated.

10.7 Internal electrical circuits and connections

Is the panel builder's responsibility.

10.8 Connections for external conductors

Is the panel builder's responsibility.

10.9 Insulation properties10.9.2 Power-frequency electric strength

Is the panel builder's responsibility.

10.9 Insulation properties10.9.3 Impulse withstand voltage

Is the panel builder's responsibility.

10.9 Insulation properties10.9.4 Testing of enclosures made of insulating material

Is the panel builder's responsibility.

10.10 Temperature rise

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices.

10.11 Short-circuit rating

Is the panel builder's responsibility. The specifications for the switchgear must be observed.

10.12 Electromagnetic compatibility

Is the panel builder's responsibility. The specifications for the switchgear must be observed.

10.13 Mechanical function

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed.

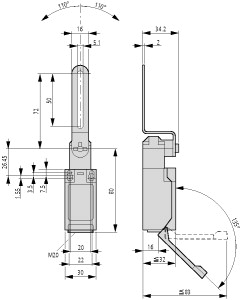

View larger

View larger

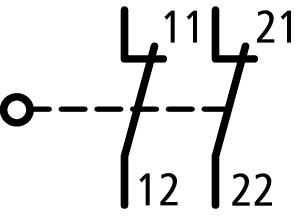

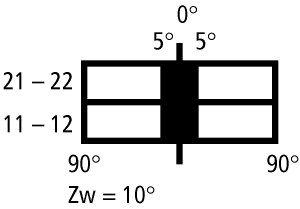

= safety function, by positive opening to IEC/EN 60947-5-1

= safety function, by positive opening to IEC/EN 60947-5-1